INSTALLATION, MAINTENANCE SERVICE

We provide installation services for production lines, industrial machinery and auxiliary systems. After receiving the requested information from customers, the company will send technicians to survey and advise customers on the implementation process, construction methods as well as installation costs.

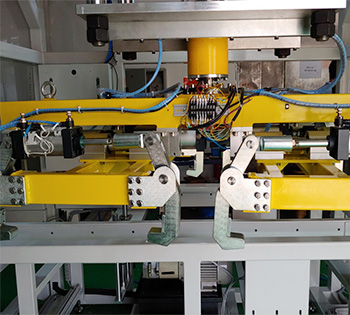

Installation of industrial systems and lines

The criteria we always put on top are:

- Good price

- Guaranteed progress

- Perfect warranty

- Reputation, sustainability.

Maintenance service, overall maintenance in the factory

We offer 2 types of maintenance services:

1. Maintenance and maintenance according to the process:

Step 1: Survey and consulting services.

Step 2: Make a maintenance and repair plan.

Step 3: Organize the construction.

– Step 4: Trial operation and calibration.

– Step 5: Acceptance, handover to use

According to the forms:

* 24/7 quick repair service: respond immediately when there is a request for troubleshooting or equipment not working, regardless of day and night or holidays.

* Package repair service by month/quarter/year

2. Maintenance and maintenance as required:

Maintenance and repair items in industrial production lines include:

- Maintenance of mechanical equipment system

- Maintenance of electrical equipment system

– Maintenance of hydraulic systems, cyclones

– Maintenance of the system of tanks, cooking tanks, mixing tanks

– Maintenance of compressed air system

- Maintenance of production and packaging systems

– Maintenance of UHT sterilization system, waste treatment

– Maintenance of other auxiliary systems

Carry out periodic inspection and maintenance of equipment in accordance with the manufacturer's recommendations and regulations; provide equipment and spare parts for repair, replacement and maintenance work (if required by customers).